Case Studies, Design, Designers, Education/Learning, Entrepreneurship, Business Devt.

Design and Business Education for Handloom Weavers in India: Innovation, Tradition and Entrepreneurship

Clifford, Ruth

Issue 04,Winter 2020

By Design: Sustaining Culture in Local Environments

Issue #004, Winter, 2020 ISSN: 2581- 9410

Introduction This essay draws upon my PhD research on design and business education for traditional artisans in India, carried out in three periods of fieldwork between 2015 and 2017. The research was shaped around case studies of two institutes started in the last decade that aim to reduce the gap between the artisan and a high-end market, to increase the value of craft amongst the market and the artisans, and to sustain livelihoods: Somaiya Kala Vidya in Kachchh district, Gujarat; and The Handloom School in Maheshwar, Madhya Pradesh. The research focuses specifically on handloom weavers and addresses the following questions: how does design education fit the local context? who owns traditional and other designs? what is the value of craft from the viewpoint of the artisan-designer as well as that of the market? It also explores how traditional methods of learning to weave compare with learning and applying contemporary design concepts. My understanding of traditional practices was enhanced by undertaking a short apprenticeship in weaving in Bhujodi village, Kachchh. This essay reveals the experiences of the weave...

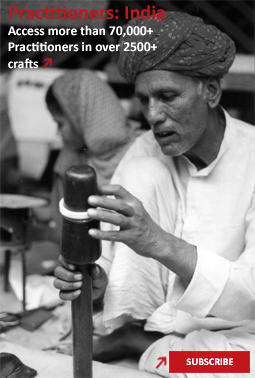

This is a preview. To access all the essays on the Global InCH Journal a modest subscription cost is being levied to cover costs of hosting, editing, peer reviewing etc. To subscribe, Click Here.