Warp beam,

A board or rod which holds the warp threads in a frameless backstrap tension loom. It may be a flat board around which a discontinuous warp is rolled, or a bamboo roller for a continuous circulating warp. Beam at the back of the loom which rotates and holds the warp.

A board or rod which holds the warp threads in a frameless backstrap tension loom. It may be a flat board around which a discontinuous warp is rolled, or a bamboo roller for a continuous circulating warp. Beam at the back of the loom which rotates and holds the warp.

Warp ikat,

The ikat-resist dyeing process applied only to the warp threads so that the warp threads are patterned before weaving. The fabric is woven to achieve a predominantly warp-faced weave. See also ikat, warp-faced.

The ikat-resist dyeing process applied only to the warp threads so that the warp threads are patterned before weaving. The fabric is woven to achieve a predominantly warp-faced weave. See also ikat, warp-faced.

Warp printing,

The printing of warp threads before weaving, which gives an indistinct design when the weft threads are introduced.

The printing of warp threads before weaving, which gives an indistinct design when the weft threads are introduced.

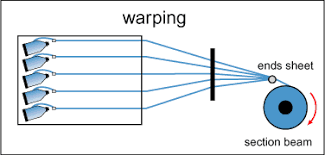

Warping,

To wind or string the warp threads on to a frame or loom by laying out threads of equal length parallel to each other. The Warp is a set of threads attached to the loom lengthwise before hand loom weaving begins. Warping is the process of creating the base yarn that runs along the length of fabric through which the "Weft" yarns are filled in to make the fabric. For a 46-inch wide fabric, over 3200 individual yarns run along the warp of the fabric. Typically, 1,96,550 yarns of yarn are aligned by wrapping them around the circular warping drum.

To wind or string the warp threads on to a frame or loom by laying out threads of equal length parallel to each other. The Warp is a set of threads attached to the loom lengthwise before hand loom weaving begins. Warping is the process of creating the base yarn that runs along the length of fabric through which the "Weft" yarns are filled in to make the fabric. For a 46-inch wide fabric, over 3200 individual yarns run along the warp of the fabric. Typically, 1,96,550 yarns of yarn are aligned by wrapping them around the circular warping drum.

Wash,

Background of a watercolor picture, prepared by using thin, watery paint applied quickly with large, sweeping brush strokes.

Background of a watercolor picture, prepared by using thin, watery paint applied quickly with large, sweeping brush strokes.

Watermarks,

Watermarks are a design made visible in the sheet of paper because the cross weave mesh of fibers is made thinner and less opaque in the image area allowing more light to shine through. The watermark is applied during sheet formation and is impressed father into the sheet during coloring.

Watermarks are a design made visible in the sheet of paper because the cross weave mesh of fibers is made thinner and less opaque in the image area allowing more light to shine through. The watermark is applied during sheet formation and is impressed father into the sheet during coloring.

Wax-resist,

A resist dyeing process in which a substance such as hot wax or rice paste is applied to the surface of fabric as a resist to dyes to form undyed areas of pattern. The resist is removed by boiling, melting or scrapping after dyeing. See also canting, cap, block printing, resist dyeing, stick batik.

A resist dyeing process in which a substance such as hot wax or rice paste is applied to the surface of fabric as a resist to dyes to form undyed areas of pattern. The resist is removed by boiling, melting or scrapping after dyeing. See also canting, cap, block printing, resist dyeing, stick batik.

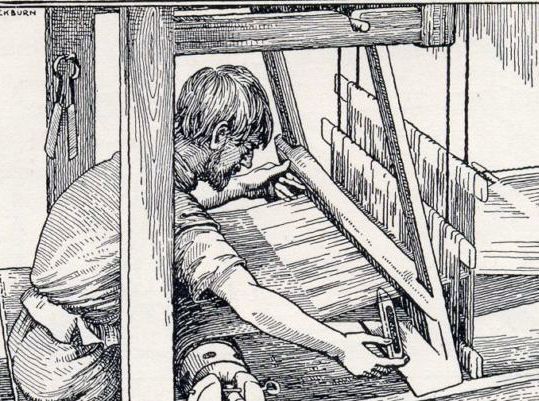

Weaving,

The process of weaving is the interlacing of two sets of yarn - the warp and the weft. The equipment that facilitates this interlacement is the loom. The process of forming a fabric by interlacing usually at right angles two or more sets of yarn. Weaving is usually done on a loom, lengthwise yarn called warp is stretched over the loom. Yarn called weft is interlaced through the warp at a right angle.

The process of weaving is the interlacing of two sets of yarn - the warp and the weft. The equipment that facilitates this interlacement is the loom. The process of forming a fabric by interlacing usually at right angles two or more sets of yarn. Weaving is usually done on a loom, lengthwise yarn called warp is stretched over the loom. Yarn called weft is interlaced through the warp at a right angle.

Weft (Woof, Pick),

The yarn in weaving that runs from selvedge to selvedge, at right angles to the warp threads.

The yarn in weaving that runs from selvedge to selvedge, at right angles to the warp threads.

Weft ikat,

The ikat-resist dyeing process applied only to the weft threads so that the weft threads are patterned before weaving. The fabric is woven to achieve a predominantly weft-faced weave. See also ikat, weft-faced.

The ikat-resist dyeing process applied only to the weft threads so that the weft threads are patterned before weaving. The fabric is woven to achieve a predominantly weft-faced weave. See also ikat, weft-faced.

Weft twining,

Two sets of threads worked together by spiralling around each other while encircling successive warps.

Two sets of threads worked together by spiralling around each other while encircling successive warps.

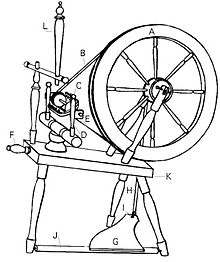

Weft Winding,

In hand loom weaving hank yarn for weft is wound on a pirn. The weft yarn is then inserted into a shuttle. Weft preparation is done on the charka, using the finger tips to give the correct tension to the yarn. This operation is normally done by women.

In hand loom weaving hank yarn for weft is wound on a pirn. The weft yarn is then inserted into a shuttle. Weft preparation is done on the charka, using the finger tips to give the correct tension to the yarn. This operation is normally done by women.