Pinchbeck,

Gold coloured brass, invented by Christopher Pinchbeck, a watchmaker of Fleet Street, London, in 1725. Probably made by melting copper and imported spelter (zinc). Later the term was widely used for all gold coloured brasses, and became a synonym for any cheap imitation.

Gold coloured brass, invented by Christopher Pinchbeck, a watchmaker of Fleet Street, London, in 1725. Probably made by melting copper and imported spelter (zinc). Later the term was widely used for all gold coloured brasses, and became a synonym for any cheap imitation.

Pitches (or pitch pins),

Fine metal pins driven into the corners of the block for the purpose of establishing the correct repeat.

Fine metal pins driven into the corners of the block for the purpose of establishing the correct repeat.

Pitching,

Finding the correct repeat. In engraved roller printing this means putting each roller in correct position while the machine is running slowly. Also known as ‘registering’ or ‘putting in register’.

Finding the correct repeat. In engraved roller printing this means putting each roller in correct position while the machine is running slowly. Also known as ‘registering’ or ‘putting in register’.

Plaid,

A checkered pattern achieved by tabby weaving different sets of coloured warp and weft threads in recurring arrangements.

A checkered pattern achieved by tabby weaving different sets of coloured warp and weft threads in recurring arrangements.

Plain weave,

The simplest possible interlacing of warp and weft elements in which weft element passes alternately over and under successive warp elements (over-one, under-one), and each reverses the procedure of the one before it.

The simplest possible interlacing of warp and weft elements in which weft element passes alternately over and under successive warp elements (over-one, under-one), and each reverses the procedure of the one before it.

- Balanced plain weave: Plain weave in which the warp and weft yarns are of the same size and interlaced with equal spacing

- Warp-faced plain weave: Plain weave in which the warp yarns are significantly more numerous than the weft yarns so that they completely hide the weft.

- Weft-faced plain weave: Plain weave in which the weft yarns are significantly more numerous than the warp yarns so that they completely hide the warp.

Plangi; Pelangi,

A resist dyeing and patterning process in which areas of cloth are reserved from dye by being bound off with dye-resistant fibres before dyestuffs are applied. Patterns are usually built up from small circles.

A resist dyeing and patterning process in which areas of cloth are reserved from dye by being bound off with dye-resistant fibres before dyestuffs are applied. Patterns are usually built up from small circles.

Plating,

The technique of applying a thin surface layer of one metal over another for decorative, aesthetic, or anti-corrosive purposes. Plating may be applied by a number of different means - Diffusion bonded plating Diffusion plating involves bringing the plating metal into intimate contact with the metal to be coated at elevated temperatures, by application of pressure or by mechanical working. The main use of this technique was for the production of Sheffield Plate - silver-covered copper sheet. Diffusion bonding was also used to produce the mokume multi-layer decorative metals used in Japan. Dip or Hot Dip In this technique the objects to be plated were dipped in a hot bath of the molten plating metal. This technique was used in the Iron Age to simultaneously plate and braze iron horse fittings rings; examples of this technique have been found at Gussage All Saints and Maiden Castle in Dorset, and Yarnton in Oxfordshire. Other examples of hot dipping to protect iron sheet from corrosion are tin plating and zinc-coated galvanized iron Electro-plating Electroplating uses an electric current to deposit the metal from solution on to the object to be plated, which acts as the cathode of the cell. The process was invented by Weiner Siemens in Germany, in 1842. His brother, Karl Wilhelm, introduced the process to Britain in 1843, where he sold it to James Elkington. This new electro-plating industry rendered the Sheffield plate industry obsolete by the latter part of the 19th century Gilding A method of putting a thin layer of high carat gold on a less expensive substrate. This includes a number of methods that are given in more detail in the section on gilding - Depletion gilding, Foil gilding, Leaf gilding, Mercury or fire gilding. Vapour deposition A modern technique in which the object to be plated is put in a vacuum chamber and the metal is thermally vaporized and deposited on the surface as a thin film. Widely used to deposit aluminium on a wide variety of surfaces. Wiping In this technique the metal object to be coated was fluxed and heated. The rod of the plating metal was rubbed over the areas to be plated. This technique was typically used for the decorative application of low melting point ‘white’ metal alloys.

The technique of applying a thin surface layer of one metal over another for decorative, aesthetic, or anti-corrosive purposes. Plating may be applied by a number of different means - Diffusion bonded plating Diffusion plating involves bringing the plating metal into intimate contact with the metal to be coated at elevated temperatures, by application of pressure or by mechanical working. The main use of this technique was for the production of Sheffield Plate - silver-covered copper sheet. Diffusion bonding was also used to produce the mokume multi-layer decorative metals used in Japan. Dip or Hot Dip In this technique the objects to be plated were dipped in a hot bath of the molten plating metal. This technique was used in the Iron Age to simultaneously plate and braze iron horse fittings rings; examples of this technique have been found at Gussage All Saints and Maiden Castle in Dorset, and Yarnton in Oxfordshire. Other examples of hot dipping to protect iron sheet from corrosion are tin plating and zinc-coated galvanized iron Electro-plating Electroplating uses an electric current to deposit the metal from solution on to the object to be plated, which acts as the cathode of the cell. The process was invented by Weiner Siemens in Germany, in 1842. His brother, Karl Wilhelm, introduced the process to Britain in 1843, where he sold it to James Elkington. This new electro-plating industry rendered the Sheffield plate industry obsolete by the latter part of the 19th century Gilding A method of putting a thin layer of high carat gold on a less expensive substrate. This includes a number of methods that are given in more detail in the section on gilding - Depletion gilding, Foil gilding, Leaf gilding, Mercury or fire gilding. Vapour deposition A modern technique in which the object to be plated is put in a vacuum chamber and the metal is thermally vaporized and deposited on the surface as a thin film. Widely used to deposit aluminium on a wide variety of surfaces. Wiping In this technique the metal object to be coated was fluxed and heated. The rod of the plating metal was rubbed over the areas to be plated. This technique was typically used for the decorative application of low melting point ‘white’ metal alloys.

Platinum,

Metallic element atomic number 78, atomic weight 195.09, mp 1772°C, specific gravity 21.45. First discovered by Western Science in South America by Ulloa in 1735, but had been used previously by the natives of Ecuador and Colombia. Finds are known particularly from La Tolita dating to the last centuries BC. The metal is malleable and ductile, however, its high melting point, well above the temperatures attainable in any medieval or earlier furnace, made it very difficult to consolidate the native metal. Hence, the early South American artefacts were of platinum sintered with gold. In the 19th century AD an attempt was made to establish a Russian coinage based on platinum coming from the Urals. In this case, the metal was consolidated by sintering the metal at high temperature and pressure. This early attempt at powder metallurgy was soon abandoned due to technical difficulties. Native platinum is usually alloyed with some iron. Sometimes there is sufficient iron present for the metal to be magnetic. Platinum was used in early scientific instruments since its coefficient of expansion is very similar to soda-lime glass. Related terms: Platinum Group Elements, PGE inclusions

Metallic element atomic number 78, atomic weight 195.09, mp 1772°C, specific gravity 21.45. First discovered by Western Science in South America by Ulloa in 1735, but had been used previously by the natives of Ecuador and Colombia. Finds are known particularly from La Tolita dating to the last centuries BC. The metal is malleable and ductile, however, its high melting point, well above the temperatures attainable in any medieval or earlier furnace, made it very difficult to consolidate the native metal. Hence, the early South American artefacts were of platinum sintered with gold. In the 19th century AD an attempt was made to establish a Russian coinage based on platinum coming from the Urals. In this case, the metal was consolidated by sintering the metal at high temperature and pressure. This early attempt at powder metallurgy was soon abandoned due to technical difficulties. Native platinum is usually alloyed with some iron. Sometimes there is sufficient iron present for the metal to be magnetic. Platinum was used in early scientific instruments since its coefficient of expansion is very similar to soda-lime glass. Related terms: Platinum Group Elements, PGE inclusions

Plique-à-jour,

In this technique, the enamel is fired into an open framework, with the result resembling stained glass. It takes on a lit-up appearance when light shines through the transparent or translucent enamels.

In this technique, the enamel is fired into an open framework, with the result resembling stained glass. It takes on a lit-up appearance when light shines through the transparent or translucent enamels.

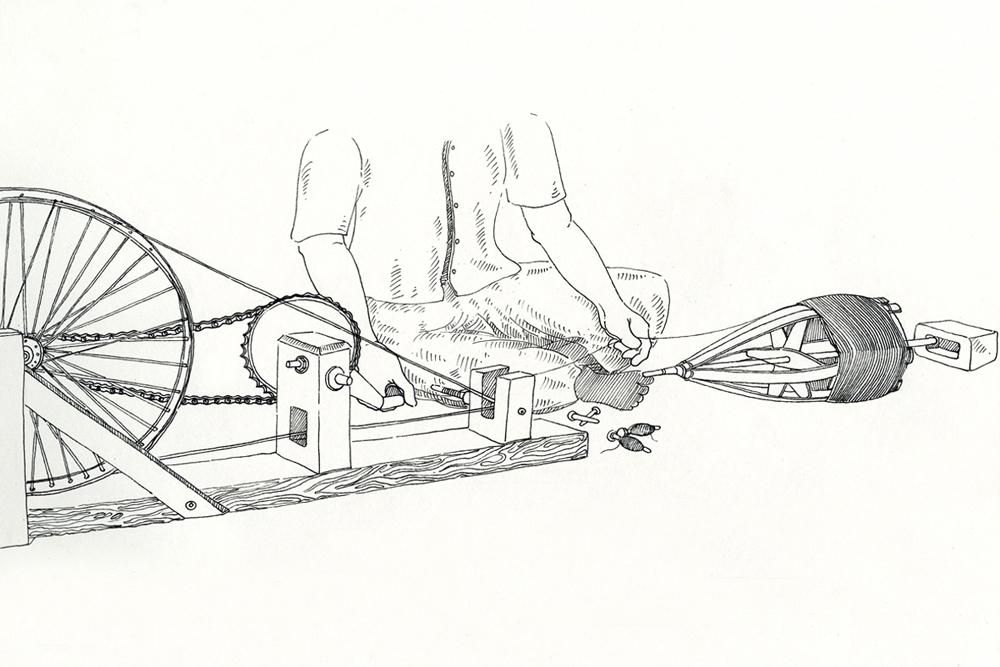

Plying,

The process of twisting together two or more single yarns. If the yarn is composed of two singles twisted together, it is said to be 2-ply, if of three singles, 3-ply, etc. Plying is usually done in the opposite direction from spinning.

The process of twisting together two or more single yarns. If the yarn is composed of two singles twisted together, it is said to be 2-ply, if of three singles, 3-ply, etc. Plying is usually done in the opposite direction from spinning.

Pokerwork,

Ornamental work produced by burning designs on to the surface of an object with a hot pointed instrument.

Ornamental work produced by burning designs on to the surface of an object with a hot pointed instrument.