The wood craft of Dharmsala is based on the Tibetan craft of wood carving. The products made include interiors of homes, architectural elements, statues, altars, boxes and musical instruments. The wood usually used are the khari, chilpine and other softwoods; the selection of the wood to be used is based on its plasticity, ease in carving and durability. The painting, lacquering and varnishing of the wood is an equally specialized task with its distinct colour scheme and style of Buddhist monasteries. The tools used are traditional and made locally from the bamboo fret saw, the bah, that is used to remove wood along the drawn pattern . with hammers, mallets, fine chisels and files.

Although less than five percent of the country's land is under forests, the material available to Pakistan's wood-craftsmen is of considerable variety. While the forests of mangrove-like trees in the coastal areas mostly provide firewood, date palms, babul (acasia arabica), farash, kikar and papal (ficus religiosa) scattered all over the sandy plains have traditionally yielded raw material for wood-craftsmen. In the hill tracts of Balochistan and the Northern Areas are found fruit trees and forests of deodar, pines, walnut, oaks, birch and willows. But by far the largest source of wood are the irrigated plantations of shisham (dabergia sirsco) and mulberry. The shisham plantations vary from large forests in Chhangamanga and Chichawatni (Sahiwal district) to rows of trees along the roads and watercourses. For each variety a different craft has been evolved.

THE CRAFT OF has long been extant in this region due to the. This huge cluster in Kirt Nagar with over 50,000 to 60,000 craftsmen engaged in crafting wood furniture was set up in 1975 by the Delhi government as a jungle of sagwan wood grew here providing the raw material needed for the craft. Working in workshop on an assembly line craftsmen specialize in executing a particular stage of the craft process whether it be the designing and transferring the farma pattern image onto the wool, or carving.

An unusual feature is that the craftsmen sell the products in an unfinished and un-polished form thereby any faults or discrepancies in the wood or workmanship can easily be identified. This furniture is then polished, finished, upholstered and sold by upmarket showrooms. The craftsmen specialize in ornate carvings on Chairs, Tables, Side tables, Beds, Cupboards, Sofas, etc

Other areas in Delhi where carving and carpentry skills are available is in Panchkuian Road and Jail Road

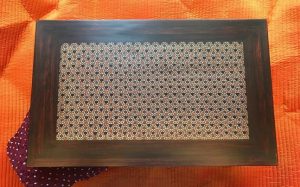

Wood inlay is the process of decorating the surface of wood by setting in pieces of material such as ivory, bone, plastic, or wood of different colours. This craft is concentrated in Mysore and Bangalore in Karnataka where its roots can be traced back to a family by the name of Mirza Yousuf Ali who were pioneers in the field. The artisan smoothens the base of the rose wood and the design is traced and etched into the surface. The several components of the inlay are painstakingly assembled to match and fit exactly into the grooves and are then glued in. The design is finished by obtaining the required shades with several coats of polish. Examples of inlay work in Karnataka include the ivory inlay in rose wood and ebony in the Srirangapatnam mausoleum; the doors of the Amba Vilas palace in Mysore are also fine examples of inlay. Products with inlay include plates, boxes, bowls, cigarette cases, and figures of animals, especially elephants, which continue to be popular. The designs include floral and geometric patterns, landscapes, pastoral scenes, processions, and scenes from the epics.

Punjab has its own wood work centers and each one has its own distinct style. Hoshiarpur, Jalandhar, Amritsar, and Bhera are known for their furniture and the carving is low relief with geometrical, floral, and animal designs. In Hoshiarpur, wood inlay work is done and the wood used is shisham or black wood, both as ground wood and with inlay. The articles made are tea pots, boxes, trays, table legs, screens, bowls, and chess boards. A popular and traditional product of Punjab is the pidhi, a wooden frame with an inside seat of woven jute sutli or cotton threads, twisted or untwisted. The designs are geometrical and the motifs are incorporated by weaving techniques. The normal height of a pidhi is 6 inches to 8 inches. With modern innovations they are raised in height, and made similar to a chair.

The wood inlay craftsmen in the beginning used ivory for the inlay work but ivory has now been replaced with bone. Plastic, different woods, shell and acrylic are also being used.

Wood is first seasoned and the design drawn on it with a pencil. The pattern is engraved onto the wood and the designs are carved out.

The acrylic sheets or whatever inlay material is to be used are cut carefully as per the design and after that set into the carved recess of the base wood with a mixture of adhesive and sawdust.

Beautiful metal inlay with brass or copper wires is also done. After inlay the surface of the wood is leveled and a thin layer of beeswax is applied to the surface in order to give it smoothness and gloss.

Intricately carved jewelry boxes, and other decorative and utilitarian items are crafted. Traditional techniques of decorative wood work, carving, inlaying, turning, and lacquering are being applied now to high-quality furniture and accessories.

There are many palaces in Rajasthan where the doors are inlaid with ivory in intricate floral or geometric patterns. The same craftsmanship is found in thrones, howdahs, and horse or camel saddles. Mirror-inlay work on wood is of Persian origin. Here the glass is blown by the craftsperson at the site of decoration and while it is still hot mercury is poured in to mirror the concave insides. Then the blown mirror-glass is broken into small pieces and shaped according to the pattern drawn on the wooden wall. These are fixed with plaster or lime.

Etikoppaka – a small, dusty village with a population of 12,000 in the Vishakhapatnam district is known for its wooden laccoloured objects. Practiced from many generations, this craft historically documented since the 1830s can be taken back to the time of the Bahmani sultanate. Etikoppaka craft has persisted and survived great hardships and its journey till today speaks volumes about the resilience of this craft form. In the post-independence period, shrinking local demand and low prices resulted in the migration of artisans to urban areas in search of mere jobs. It is even said that out of a total 225 weaving families, there was a time when only one old artisan and his wife were left in Etikoppaka. Post 1990, the introduction of synthetic dyes led to the initial distortion of traditional practices considered essential for the craft. The use of natural dye extracted from the now extinct local tree called Divi-Divi (Caesalpiniacoriaria) for tones of red, formed an important part in the production process. In the early years of the 20th century in the midst of hardships and the inevitable extinction of this craft, one man saw immense potential and took up the challenge of reviving Etikoppaka. C V Raju – the head of the local landowning family took a keen interest in the local craft of lathe turned and lacquered wood. His efforts to revive the eco-friendly wood-lacquer process with a focus on natural dyes and efficient processes has brought the artisans back to life who are said to have shifted back to their original craft based occupation. Approximately 200 artisans belonging to VishwaBrahmin, Devanga, Gouda, Padmasali, Konda, Settybaliga and Kapu castes practice this craft. Lac and AnkudiKarra (Wrightiatinctoria) or Ankudu wood form the main raw materials used in the Tharini or the turned wood lacquer process. Ankudu wood comes from a soft tree also known as soft ivory-wood grown abundantly in the local forests. Branches and trunks of the tree are used to create different objects. The application of Lac was introduced by C V Raja. Lac is a resinous substance used to impart colour to the wood. There are two types of lac known as Rangeen and Kusumi, where the latter is considered to be of superior quality. The tools used are basic and consist of a planer, saw, cutting tools and hand drills. The wood is seasoned and cut to suitable length. The lac sticks are used to lacquer the items. The lac is further oxidized with natural vegetable colour and then applied to the carved wood piece turning on a lathe.Mogalireku (kevda leaf) is used for finishing and flair to the product. Lacquer work is an extensive process and can be performed either by lathe, machine or hand. Revival of the craft was again led to the identification and use of various natural and vegetable dyes with available colours ranging from previously available tone red to ochre, olive, turquoise and indigo blue. Etikoppaka originally consisted of wooden articles made for domestic and religious use. Moreover, toys, mythological figures and carvings are said to be exquisite belonging to the Etikoppaka craft. To tap the market potential, various home décor and decorative items like ornaments, cups, lamps, bangles, jewellery boxes, photo frames, cutlery, table ware, and oil bottles form some of the recent and popular products. These products have also found a good market overseas. Efficient technology and application of traditional methods have resulted in steady improvement of the Etikoppaka craft. However, to say that the problems surrounding the Etikoppaka artisans have diminished would be fallacious. Stringent export norms, eroded markets with cheaper non-original copies of Etikoppaka are some of the issues which require attention. Moreover, inadequate supply of wood threatens to weaken the stability of the artisans. The forest department imposes a fine on the artisans if wood is obtained directly and thus, the artisans remain dependent on middlemen and vendors. Awareness of the craft has led to various institutions of fine art of Andhra Pradesh, NID, and NIFT to get involved in the designing and further development of Etikoppaka craft. Moreover, various societies such as Padmavati Associates, EtikoppakaVanaSamrakshanaSamiti (Forest protection committee) continue to work towards preserving and conserving the existing and future wood stock required for Etikopakka.

Kutch is well known for its crafting of wood and lac turnery which is undertaken by a semi-nomadic community of lathe turners and carpenters called the Meghwals and Maniars. An indigenous lathe is used to turn and shape wood. It is then embellished with a vegetable colors and lac. Articles such as mortar and pestle, rolling pins, legs of tables and cots, cabinet and chests, dandia(sticks used in local dances etc are produced by the craftspeople. The tools employed for the crafting process are axe, wooden axle and lathe and iron bar support etc. Lac is obtained from an insect called kerria lacca and is in a resinous state. Amidst the rich heritage of art and craft in Gujarat, lac is another popular craft that has been produced across centuries. It is mainly used to make jewellery such as bangles, earrings and jewellery boxes, along with other decorative pieces. Gujarat's lac work on bangles is exquisitely embellished with various precious and semi-precious stones. They are famous for there embellishments and vibrant, exotic colours.

Surat is known for marquetry called sadeli. Thin and long strips of ebony, ivory, red wood, bone, and tin are stuck together to make the design. This craft was at one time used to ornament the doors of palaces and mansions; now it is also used to decorate wooden articles, especially boxes. This is not inlay work, but more in the nature of appliquè and involves no carving.

The process involves making a long belt of match sticks prepared by using fevicol. Thereafter the belt is cut in the required shape, i.e., doors, ceilings, windows, pillars, stairs, etc. These small pieces are moulded by giving light pressure by hand. Finally, all small pieces are fixed with fevicol in the desire shape. The cost of raw material is minimal but the entire process is very labour intensive and requires high level of skill for making such masterpieces.

This is a very popular craft in Karnataka and is widely practised. Rosewood inlay work is done using wood shavings of various shades and hues; chips or shavings obtained when elaborate woodwork is done is used for the craft. The pattern is traced into a piece of rosewood suitable in suitably shape and size. Then wood chips in differing shades of brown, yellow and beige are used to fill in the pattern. Elements requiring other hues are created by painting directly on to the picture. This wood collage is assembled very carefully as the chips chosen have to be inset neatly. The whole picture is then given a veneer of polish, making it rich and glossy. The themes found in wood patchwork include rural scenes, historical depictions, religious figures, deities and vivid examples of nature in all its scenic beauty.

Wood-carving has, traditionally, been the forte of the Nepali artisan - using the most primitive of tools they have, over the centuries, endowed the simplest of products with great aesthetic appeal without detracting from their utilitarian value.

- Theki: In carving a theki, a log of wood, preferably cedar, is rotated horizontally and a curved tool is used to slice the wood. As the log of wood rotates, it is scooped little by little. After the required depth is cut, it is refined further and the exterior portion is also cut, giving it the required shape. Thekis come in different sizes with little variation in their shape. They are used for preparing and churning the yogurt.

- Singmang: It is believed that clarified butter or ghee can be kept in a singmang for several years without any preservative.

- Ari: Bowls or ari made of wood are used in making pickles. Any edible item can be kept in such bowls.

The Bhutanese produce a variety of highly prized utilitarian turned wooden bowls, cups, plates, dishes and containers, all of which they use in their daily life. These bowls and containers come in different shapes, sizes, and colours, which distinguish the different uses that each is put to - a monk's bowl, a serving bowl, a rice bowl, or a soup bowl being common examples. Made from wood with the help of slow-revolving, pedal-operated lathes, these bowls remain unaffected by heat or liquid and are lacquered with indigenous materials. Often, the smaller tea or soup bowls may be inlaid with silver, which makes them even more attractive and also enhances their lasting ability.

- Thokey: Fruit BowlA traditional article, that is used during religious ceremonies and on special occasions.

- Tsamdeg: Serving Bowl with LidThe Tsamdeg was originally used for tsampa (barley or wheat flour)The product originated in the north and extreme east of Bhutan where roasted wheat and barley flour comprised the staple diet.

- Baw Dapa: Rice Plate with Lid The Baw dapa with a lid is traditionally used to serve rice in. The dapa is 10 inches in diameter and has a lid. It is used especially by lamas, monks, and dignitaries.

- Dumchem Dapa: Rice Plate with LidThis wooden round container with a lid is traditionally used to serve rice in.

- Gophor: Cup with Lid The gophor is traditionally used for drinking liquids like tea and soup.

- Laphor: Bowl with Lid The laphor is traditionally used by the monastic community, for tea and soup.

- Boephor: Cup The beophor is traditionally used for drinking wine, curry, or tea. People carry it on their persons, saving their host from having to provide cups when serving liquid refreshment. Men carried two cups wrapped in cloth plus a knife at the waist, while women carry one cup. It is wiped or washed with warm water.

- Za Phob: Burl Cup It is the Bhutanese ceremonial cup of wooden burl with natural lacquer used to drink tea and wine in.

- Samden: This is 1" height and 1"foot broad and is used for serving snacks in.

As with all the zorig chusum, shingzo is a devotional act, which links the craftspeople to their personal deities. For centuries houses, palaces, dzongs, temples, bridges and utilitarian items for the home and the field have been and continue to be made of a combination of stone, rammed earth, bamboo and local timber or wood. Timber is used lavishly in all structures for windows, doors, stairs, balconies, columns, beams and other structural elements and for elaborate decorative cornices. It is this lavish use of timber, which gives Bhutanese architecture its beauty, elegance and unique character at the same time making these structures highly vulnerable to fire and degeneration.

Wood work is largely practiced in Dharamshala, Himachal Pradesh. Products such as architectural elements, cupboards, statues, altars, picture frames, boxes, musical instruments etc are created under this craft from. Tools such as bamboo fret saw called bah, wooden mallet, sharpening stone called jamdar, chisels, gouges, metal pointer, calipers, template, files and sandpaper are needed for the production process.

The block makers' village is in Bora about 15 kms from Serampore, off the GT Road. Serampore is about 25 kms from Kolkata to the North, on the west bank of the Hooghly. Earlier known as Fredericknagore it is one of the few places in India that was colonized by Denmark from 1756 to 1845.

Though the origins of block carving are lost in the folds of history, we have examples of block printed fabric dating back to 2000 B.C. Evidence has been found that the art of dyeing fabrics was practiced in the Indus Valley Civilisation. According to the 1961 Census conducted by the Government of India, the craft was developed and specialised by the Suthar artisans who were traditionally carpenters. The document also mentions that the craft might have been adopted from Iran at the time of the Mughals and concentrated in Shikarpur in Sindh from where it spread to Gujarat. This is in keeping with the theory that the skill of block printed fabrics travelled from Sindh to the modern Indian states of Rajasthan, Gujarat and Western Madhya Pradesh. The block makers of Pethapur believe that many centuries ago, women got tired of their white unembellished clothes and began using their bangles dipped in colour to pattern their garments. The carpenters noticed and decided to provide the women with various designs and so gave rise to the tradition of hand block printing on textiles. Most of the craftsmen engaged in this work belonged to the Gajjar Suthar caste who believe that their ancestors settled in Pethapur some 200 years ago. The caste believes it is the progeny of Vishvakarma, the architect of the gods1. Like the hand block printers, block making is an endangered craft. These talented craftsmen, similar to so many other craftspersons in India, face the problem of situating themselves within the contemporary market economy, in attempting to create and develop products which might curb the widening divide between greater supply and diminishing demand. The block makers had a few prominent clusters in Pilakhuwa, Farukhabad and Ahmedabad which supplied the printers of the country. It is from Ahmedabad that the block carvers migrated to Pethapur, which today is the only remaining centre in the country solely making wooden blocks. It supplies to all the hand block printing communities from Sanganer (Rajasthan) to Bagh (Madhya Pradesh). In other centres, Pilakhuwa for instance, the block makers have applied their carving techniques to making wooden tables, boxes, photo frames, pen holders etc to broaden their market and continue their trade. Pethapur, situated 40 kilometres from Ahmedabad, is the only surviving centre of wood block carving. Blocks are ordered and sold directly between the printer and carver with no middlemen or agents. Either the block maker travels to the printing centre with his directory of designs on which orders are taken or the printer goes to the carver, either ordering from the block makers design repertoire or giving his own design layout.

1 Census of India 1961:7.

|

|

|

BRASS BLOCKS

An alternative technique to carving in wood is blocks where the designs are created by attaching metal wires or strips to a wooden base. Such blocks are almost always (rekhs) and save the labour of carving the main block. |

2Tectona Grandis or Indian Oak. 3The Census of India of 1961 refers to the data blocks as datla 1970:14